Industry

Temperature and Vibration Monitoring of Critical Components in Production

Temperature and Vibration Monitoring of Critical Components in Production

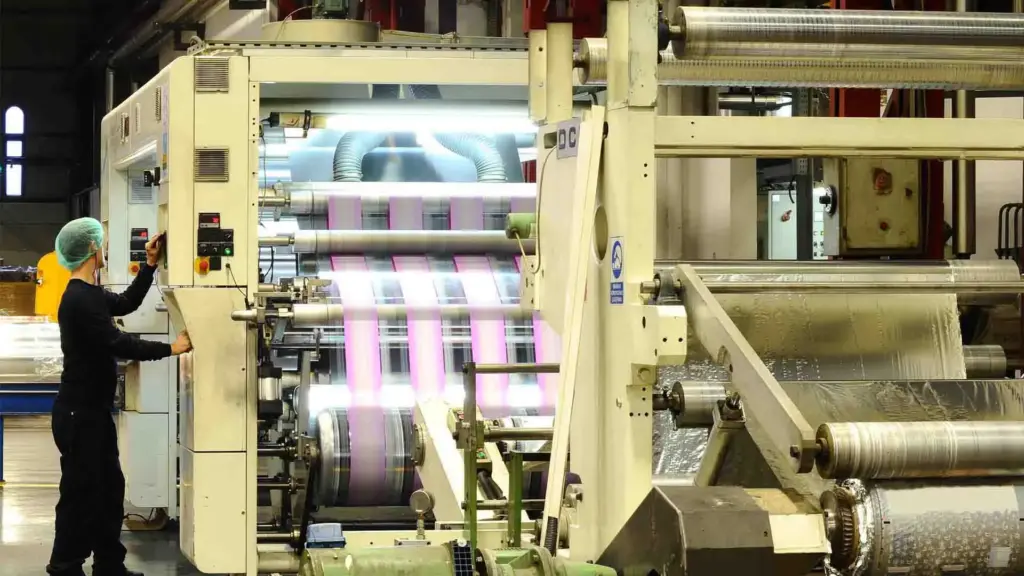

Let’s look at an example of building an IoT network at a cardboard packaging factory. Here, the Internet of Things was used to create a wireless equipment vibration monitoring system.

Temperature and vibration frequency can indicate early signs of equipment failure. Therefore, the factory needed to monitor bearing vibration and lubricant quality. If the bearings are insufficiently lubricated, friction increases, the equipment overheats and vibrates more — leading to breakdowns, repairs, and bearing replacements, which can be costly.

The factory considered two vibration monitoring approaches: Wi-Fi-based data collection or analog sensors. The problem was that analog sensors required new cabling, while Wi-Fi temperature sensors needed a constant communication channel for data transmission — meaning continuous battery operation.

The task for iotji was to find a wireless alternative to vibration and temperature sensors with low power consumption.

Industrial LoRaWAN temperature sensors allow monitoring of the heating degree of electric motor windings and bearing temperature. As for vibration sensors — they can measure vibration velocity and vibration acceleration along one or all three axes. Smart pressure sensors perform measurements in harsh industrial environments, ensuring reliable process monitoring at the factory.

LoRaWAN is a data transmission protocol ideally suited for measuring vibration and heating of industrial equipment, since such parameters require only small data volumes. The advantages of LoRaWAN systems are highly valued at production enterprises due to their wide coverage and ease of installation:

A single LoRaWAN base station provides reliable coverage for the entire workshop area.

Almost all operating parameters of equipment can be collected using LoRaWAN sensors — the range is extremely broad. To select the right one for your task, contact us at sales@iotji.io.

Magnetic mounts make sensor installation easy and secure on industrial machinery.

The energy-efficient LoRaWAN principle allows sensors to operate for several years without battery replacement. Most of the time, devices remain in sleep mode and wake up only for a few seconds to transmit collected data.

LoRaWAN data collection systems are highly resistant to industrial narrowband interference, so data is transmitted without loss. Moreover, the iotji team can route all collected data to the plant’s existing SCADA system for visualization and control.

The core of any IoT project is its software layer. In this vibration monitoring project, it is the LoRaWAN Network Server (LNS) — which ensures communication between sensors, actuators, and gateways. The LNS then sends data to the LoRaWAN Application Server (LAS) responsible for business logic. The LNS–LAS pair typically communicates via the MQTT protocol, ensuring flexible data exchange.

To transfer information from LAS (ThingsBoard PE) to SCADA systems supporting OPC UA (for example, Siemens WinCC, Schneider Electric EcoStruxure, or OpenSCADA), an integration mechanism is used to enable two-way data exchange between the OPC UA Server and LAS within the plant’s IIoT network.

Using Industrial IoT (IIoT) technologies enables a shift from periodic measurements to continuous monitoring, significantly extending the ability to predict equipment failures. Adding artificial intelligence (AI) for data analysis makes the entire system even more effective, allowing the detection of long-term trends. You can read more about AIoT here.

With optimal and critical thresholds for machine temperature and vibration frequency defined, iotji designed a wireless vibration monitoring system. All data collected from machine checkpoints via LoRaWAN is processed and visualized in the ThingsBoard PE IoT platform, and also integrated into the factory’s existing SCADA system. LoRaWAN–SCADA integration is especially useful during production process reconfiguration or equipment relocation.

The low-maintenance operation of LoRaWAN sensors allows the data collection system to run for years without technical servicing, thus optimizing production costs.

After deploying the LoRaWAN network, the factory is already preparing to expand sensor functionality — in particular, connecting current sensors for detailed energy consumption monitoring for each unit of equipment. This will allow precise cost planning and accurate product cost calculation. The LoRaWAN network will also enable integration of other industrial systems such as motion sensors, door/window open-close sensors for access tracking, and an 868 MHz smoke siren as part of the fire safety system.

For those who use household refrigerators